In ME 104, also called Mechanical Systems Design, I had the opportunity to gain hands-on experience through three engineering challenges revolving around a moving hydraulic press.

Working individually and then on a team, I designed and manufactured three machines with one objective each:

Withstand compressive force,

Approximate a linear resistance force, and

Maximize exerted force on a moving platen.

Right: Fusion 360 renditions of each project.

Class Project (ME 104)

Winter 2025 - Stanford University

Mechanical Systems Design

Project 3 Demo

“Flattened Stop Sign”

2. “Lambda”

3. “The Very Hungry Caterpillar”

Contraptions were scored on their respective criteria, as well as mass optimization relative to the rest of the class.

Project 1 - Compressive Force

I was tasked with minimizing mass on a structure that would withstand at least 200N of force from the platen. We were not allowed to put mass inside a “non-interference” (NI) zone that comprised a volume in the middle of the build area.

I opted for a symmetrical, elongated octagon (3D printed in PLA) that bent around the NI zone. Horizontal supports in the middle mitigated buckling. I used FEA to find weak spots to reinforce and refine before test day.

My design passed the challenge!

Project 2 - Linear Force

Next, I was tasked with designing a structure that would convert a spring’s stored potential energy into an approximately linear output force as the platen moved downward onto it. The same NI zone rule from Project 1 applied.

With a partner, I designed a lambda-shaped device that extended the spring outward. We chose to 3D print it out of Tough 2000 based on relevant calculations.

Our design passed the challenge!

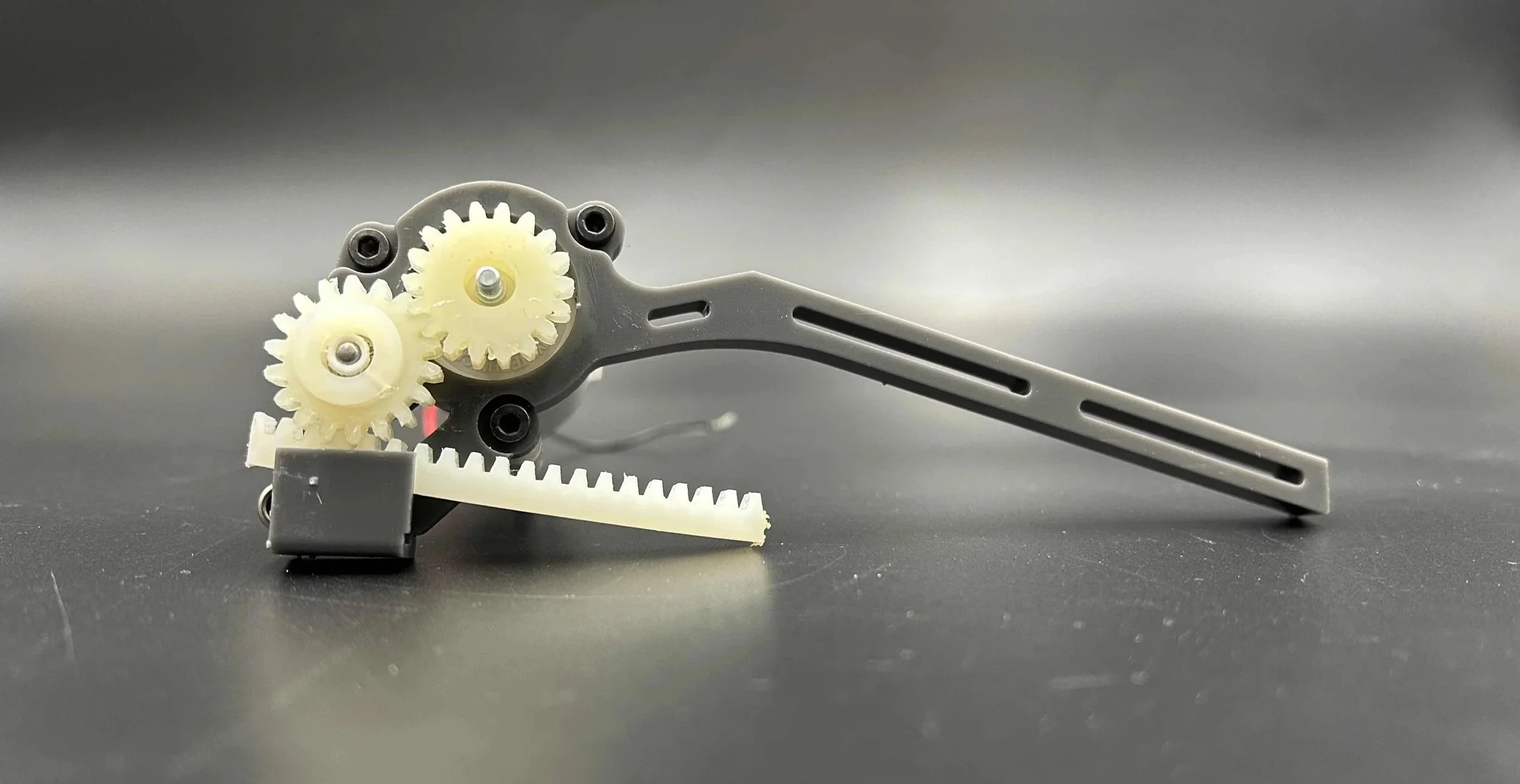

Project 3 - In Motion

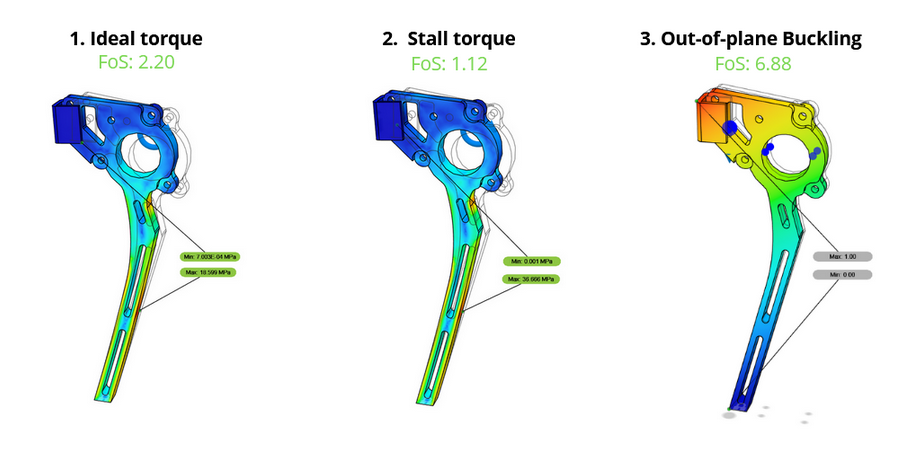

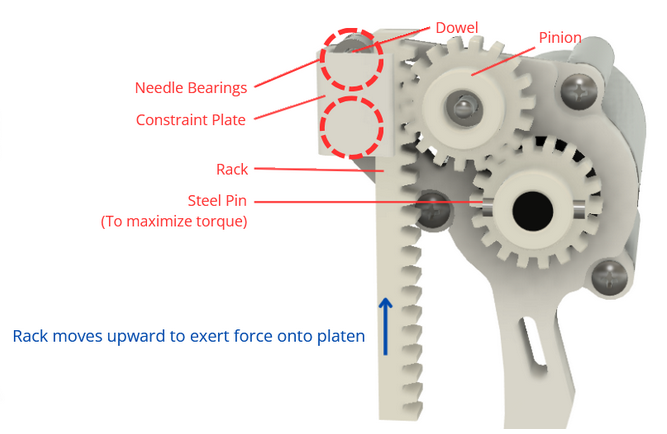

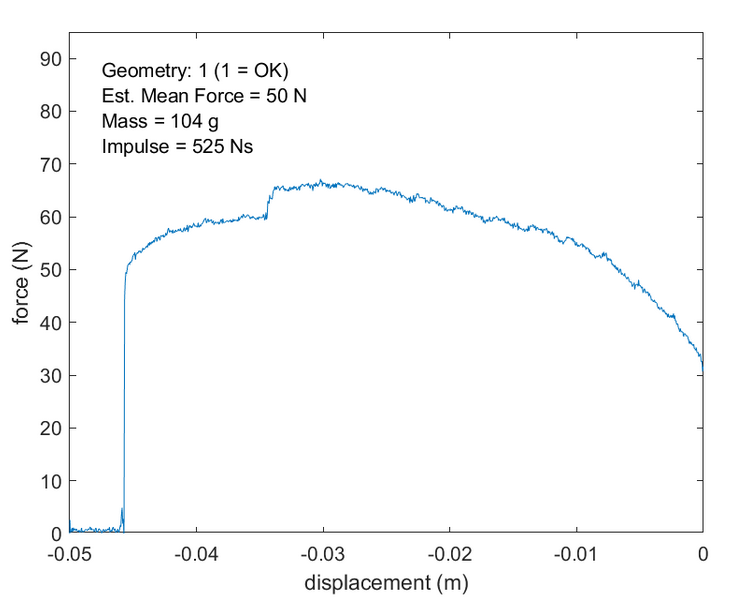

For the final project, I and two teammates designed a motorized contraption to maximize output force on a platen moving away over time. We were given a motor kit and gearboxes, and we ended up using a 120:1 gear ratio to balance torque and the upward velocity of the rack to match the moving platen.

We sourced the parts ourselves and constructed a BOM to document expenses. We again opted for Tough 2000 resin for the main body. We also ordered nylon gears to optimize for mass while being able to handle the forces we both calculated by hand and confirmed by FEA.

We ended up exerting 525 Ns of impulse, which was well above the class average!